NAKAYAMA DENDOMAN(CRAWLER-MOUNTED CONE CRUSHER UNIT)

| MODEL |

NE200C |

| TYPE |

Crawler-mounted, Electro-hydraulic drive, 1- stage crushing by cone crusher, |

| CAPACITY |

110-300TPH |

| FEED MATERIAL |

Rock and concrete waste |

| MAX. FEED SIZE |

90 x 125 x 180mm |

| WEIGHT |

Approx. 37,700kgs |

| TRAVELING SPEED |

0.8Km/h |

| TRAVEL CONTROL |

Manual travel lever |

| CLIMBING ANGLE |

Approx. 20° |

| PRESSURE ON THE GROUND |

Approx. 93Kpa |

SPECIFICATIONS

- COMBINATION OF ELECTRIC & HYDRAULIC POWER : Power supply is from generator or industrial power supply. Cone crusher and other equipment are driven by electric motor for easy control, while traveling power is by hydraulic motor driven by electric motor.

-

HIGH PERFORMANCE : Job-engineered high-performance cone crusher, with the lowest profile in this machine size range. The optimum biting geometry and timing give higher production.

-

CRAWLER MOUNTING : Crawler mounting offers easy installation and move within the site area.

-

HYDRAULIC SETTING ADJUSTMENT : Hydraulic system with ring gear gives easy and quick crusher setting adjustment.

-

OPTIONAL : Magnetic separator

NAKAYAMA DENDOMAN(CRAWLER-MOUNTED CONE CRUSHER UNIT) NE250J

| MODEL |

NE250J |

| TYPE |

Crawler-mounted, Electro-hydraulic drive, 1- stage crushing by jaw crusher, |

| CAPACITY |

50~250TPH |

| FEED MATERIAL |

Rock and concrete/asphalt waste |

| MAX. FEED SIZE |

450 x 800 x 1,000mm |

| WEIGHT |

Approx. 37,000kgs |

| TRAVELING SPEED |

0.8Km/h |

| CLIMBING ANGLE |

Approx. 20° |

| PRESSURE ON THE GROUND |

Approx. 118Kpa (1.2kgf/cm2) |

SPECIFICATIONS

- COMBINATION OF ELECTRIC & HYDRAULIC POWER : Power can be supplied either from generator or from industrial power supply.Jaw crusher and other equipment are driven by electric motor, while traveling power is by hydraulic motor driven by electric motor.

-

POWERFUL BITE & LARGE FEED OPENING : Job-engineered powerful jaw crusher with 1,050x500mm feed opening and optimum biting geometry gives high performance in crushing rocks and concrete waste.

-

CRAWLER MOUNTING : Crawler mounting offers easy installation and move within the site area.

-

HYDRAULIC SETTING ADJUSTMENT : Hydraulic system gives easy and quick jaw crusher setting adjustment.

- AUTO FEED CONTROL : Feed rate to the crusher is automatically controlled depending on the crusher load

-

OPTIONALS : 1, Hydraulic Start Assist for smooth start and quick recovery from material jamming. 2, Magnetic Separator

NAKAYAMA DENDOMAN(CRAWLER-MOUNTED CONE CRUSHER UNIT) NE100J

| MODEL |

NE100J |

| TYPE |

Crawler-mounted, Electro-hydraulic drive jaw crusher |

| CAPACITY |

15~100TPH |

| FEED MATERIAL |

Rock and asphalt/concrete waste |

| MAX. FEED SIZE |

265 x 330 x 660mm |

| WEIGHT |

Approx. 13,000Kgs |

| TRAVELING SPEED |

0.5/1.0Km/H (Slow/Fast mode) |

| CLIMBING ANGLE |

Approx. 18° |

| PRESSURE ON THE GROUND |

Approx.96kPa |

| TOTAL POWER |

Approx. 49kW |

| DIESEL GENERATOR |

90KVA, 200V, 60Hz |

SPECIFICATIONS

- COMBINATION OF ELECTRIC & HYDRAULIC POWER : Power supply can be either from its own generator or commercial power supply. Jaw crusher and other equipment are driven by electric motor, while traveling power is by hydraulic motor driven by electric motor.

-

HIGH PERFORMANCE CRUSHER : Job-engineered powerful jaw crusher, with 600x400mm feed opening and optimum biting geometry, suitable for crushing rocks and asphalt/concrete wastes at maximum efficiency.

-

COMPACTNESS - 40FT CONTAINER SIZE 40ft : Powerful jaw crusher mounted on crawler undercarriage in a small package enabling shipment in a 40Ft container without dismantling. The compact design allows high maneuverability in operations at a site where the work space is limited especially in urban areas.

-

TRANSPORTABILITY : Compact yet sturdy structure enables easy transportation from site to site.

- CRAWLER :Steel crawler gives easy installation and quick move within the site area. Rubber pad is optionally available.

-

HYDRAULIC SETTING ADJUSTMENT :Hydraulic jaw crusher setting adjustment system gives easy and quick setting change for minimum down time.

- AUTO FEED CONTROL :

Crusher feed rate is automatically controlled depending on the crusher load to maximize the operating efficiency.

- SAFETY :

The crusher is equipped with emergency stop switch and protective covers for safety wherever necessary.

- LOW FUEL CONSUMPTION & CLEAN EXHAUST GAS : The crusher has its own diesel generator for travel and crushing operation complying with Tier 4i. High power trans- mission efficiency to the jaw crusher resulted in maximum

- CHOICE OF MORE ECONOMICAL POWER SOURCE :

Instead of its own diesel generator, this crusher can also be driven by commercial power supply, whichever is more cost-effective.

- OPERATION LOG :

The crusher is equipped with operation data recording system (Green Box). Operation status monitor, trouble records and parts replacement records can be shown on the display.

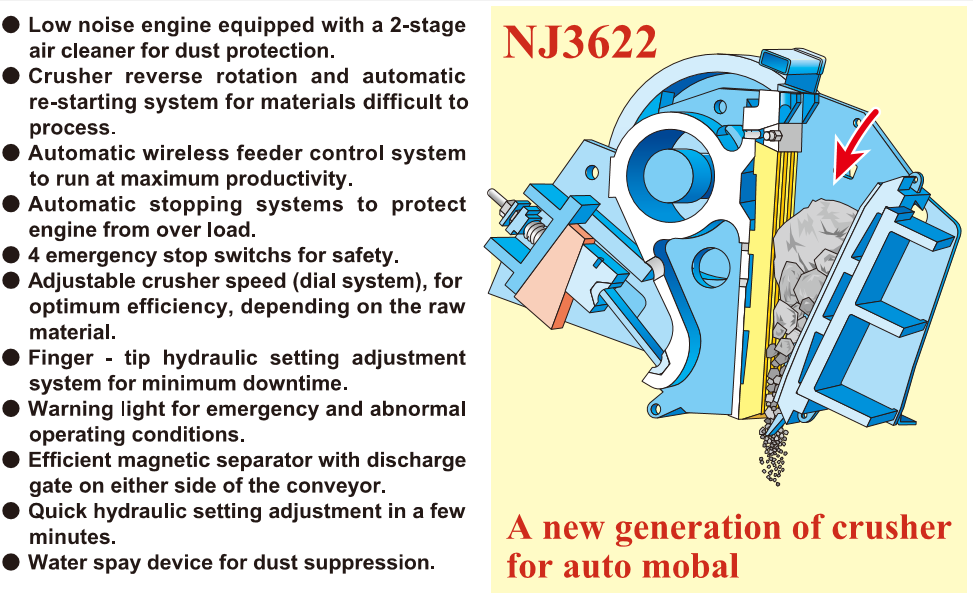

NC360GXC CRAWLER-MOUNTED CRUSHER UNIT

The NC360GXC is equipped with a new generation of low profile jaw crusher NJ3622, designed on the basis of our well - proven crushing technology. Suitable for primary crushing of rocks,as well as convrete and asphalt wastes, with unparalleled performance. Overall, the NC360GXC is a simple and rugged design with ample safety measures and easy maintenance.

SPECIFICATIONS

NC420GXC CRAWLER-MOUNTED CRUSHER

The NC420gxc is equipped with the job-engineered AC4220B powerful jaw crusher that is ro-bust enough to crush rocks

as well as asphalt and concrete wastes.

FEATURES

- PRIMARY CRUSHING AT QUARRY FACE

- QUICK SETTING ADJUSTMENT

- WIRELESS FEEDER CONTROL

- ENGINE POWER BOOST

- EASY PARTS REPLACEMENT

- JAW PLATE VARIATION

- VARIABLE CRUSHER SPEED

- LOW-NOISE ENGINE

|

- CRUSHER REVERSE ROTATION

- POWERFUL MAGNETIC SEPARATOR

- AUTOMATIC SHUTDOWN

- WARNING LIGHT

- 2-STAGE AIR CLEANER

- WATER SPRAY

- SAFETY

|

BENEFITS

- It can produce block stones.

- Finger-tip hydraulic setting adjustment in a few minutes for minimum downtime.

- Feeder remote control to maximize production

- Automatic power boost in case of peak load.

- Easy jaw plate and cheek plate replacement for minimum downtime.

- Two types of jaw plates are available for recycling and for rocks.

- Crusher speed is adjustable to run at optimum crushing speed depending on the feed material.

- For crushing difficult material and re-starting with the material between the jaws.

- Magnetic separator to seperate and discharge steel scraps an either side of the conveyor.

- Automatic stopping system to protect engine from over load.

- In case of emergency or abnormal operating conditions.warming lamp turns on

- For protection of engine from dust.

- For dust suppression(water supply by the customer)

- 5 emergency stop switches for safety.